Services

| |

Simple Questions - Difficult to Find Answers

What is this material? What size and shape are its particles? How did the material fail or corrode? How uniform is the blend or coating? These are seemingly simple questions but for engineers, scientists and quality control simple, answers are not good enough. They need to know as precisely as possible. There can be vast amounts of money on the line based on the answer to these questions. At times, lives can be in the balance.

SEMx utilizes the latest technologies and processes that delivers the most accurate data available for answering these questions and more. Our ability to combine the best of Scanning Electron Microscopy, X-ray Powder Diffraction and Laser Particle Sizing give you unrivaled data accuracy for your decision making process.

| |

Our Services

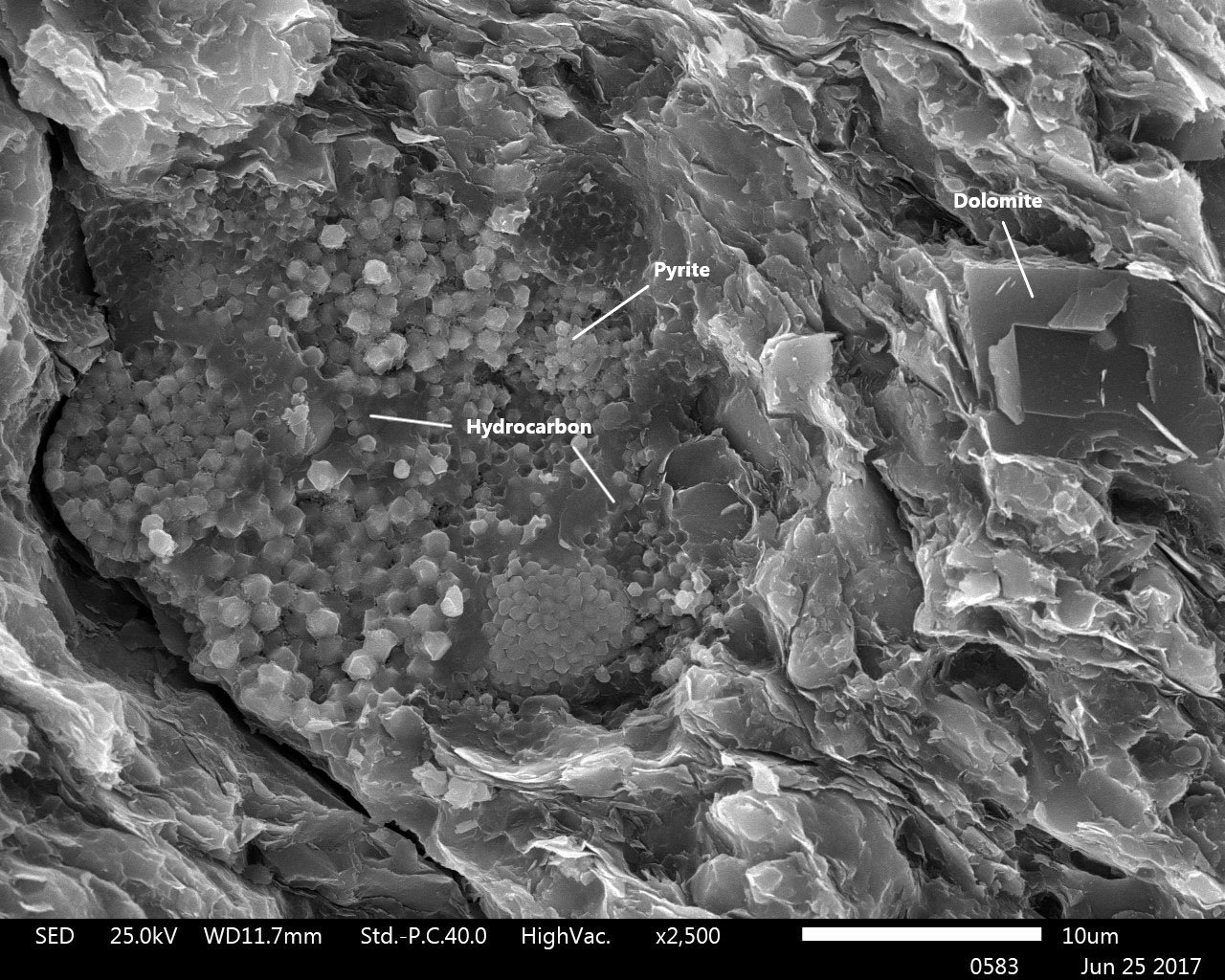

Scanning Electron Microscopy

Work with an expert operator and our 40" HD screen to meet your needs. Based on hourly rates we provide:

X-Ray Diffractometry (XRD)

X-ray Diffractometry is widely used for identification of unknown crystalline materials. Sample preparation is performed to USGS standards.

SEMx provides a unique combination of XRD quantification, Rietveld Refinement, amorphous quantification, EDS and SEM imaging resulting in precise phase identification and accurate quantitative analysis of ±1%. These enhanced results are usually produced faster than only using XRD quantification.

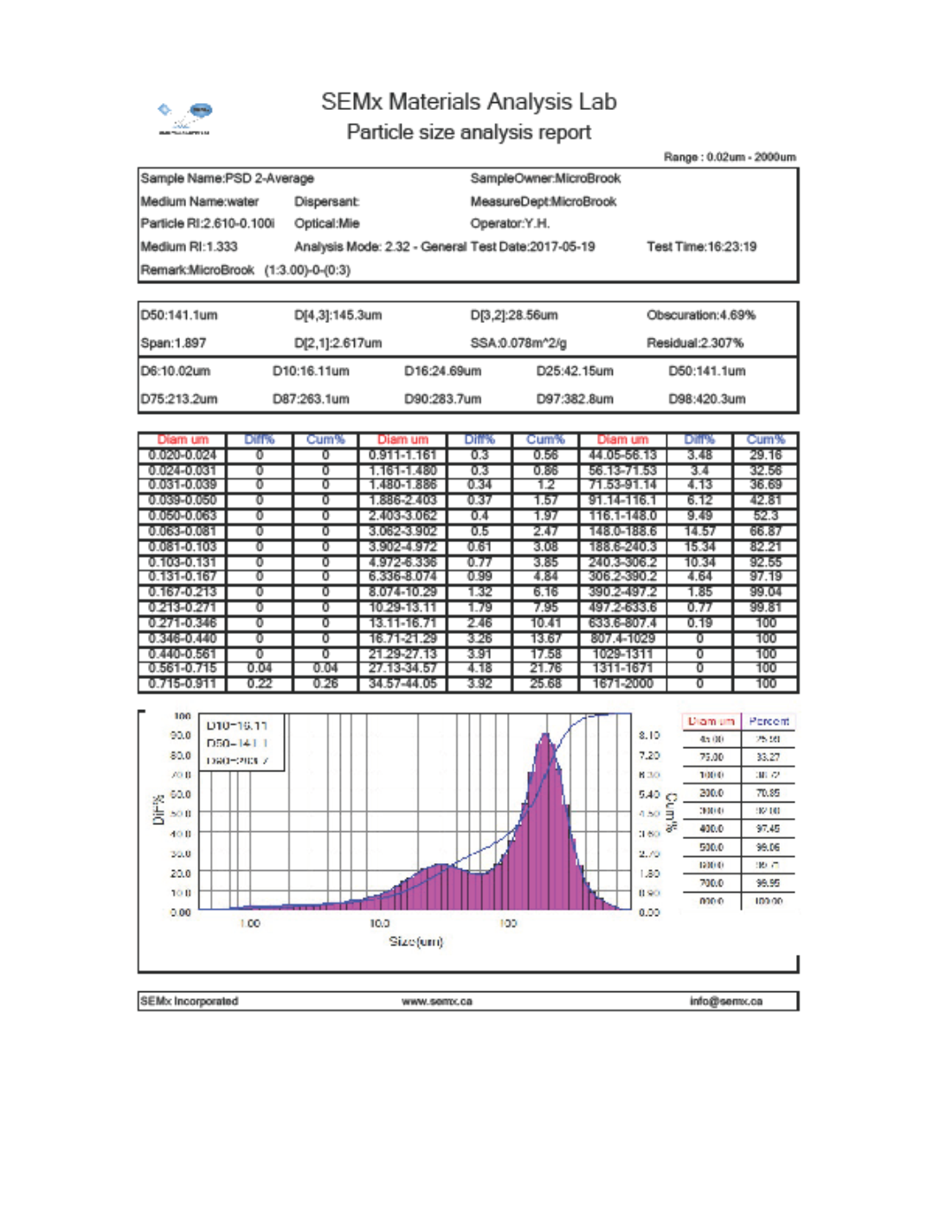

Particle Sizing

SEMx uses two methods for particle sizing - Laser Particle Sizing and Scanning Electron Microscope image sizing. Depending on whether your sample is large, small, dry, wet, soluble round or rod SEMx applies the right technology to get you the answers you need.

| |

Mix and match according to your needs

![]()

Every organization has different needs. Each project may have different requirements. SEMx is here to listen, understand and tailor our technology and services to meet your specific needs. Tell us what you are trying to accomplish. Describe your challenges and what has worked or not worked in the past. Together we will develop a plan that provides the data you need at a price that delivers clear value to your project.