Scanning Electron Microscopy

Booking time on our SEM and working with our skilled operators is one of the best ways to get answers to the questions you have about your materials. Our SEM provides the a variety of information:

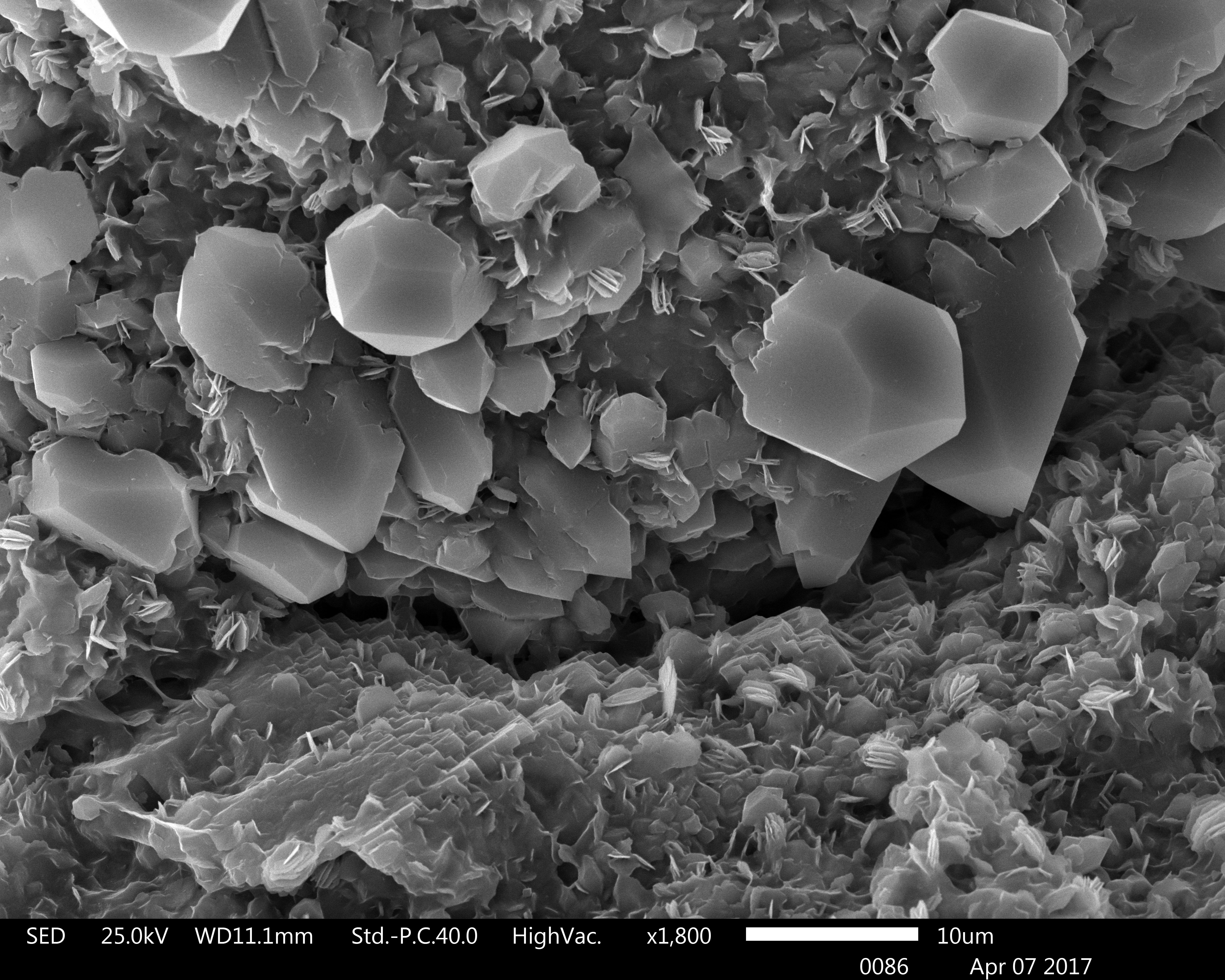

SEI - High resolution Secondary Electron Images show morphology detail on the surface of the observing sample (5 to 300,000 magnification).

BEI - Backscatter Electron Images can show the composition distribution of the elements according their atomic mass.

EDS – Check elemental composition on selected area or a tiny pinpoint location.

Line Scan – Shows the concentration change of selected elements on the specific direction.

Elemental Map – Shows the distribution and location of different elements on the observing surface.

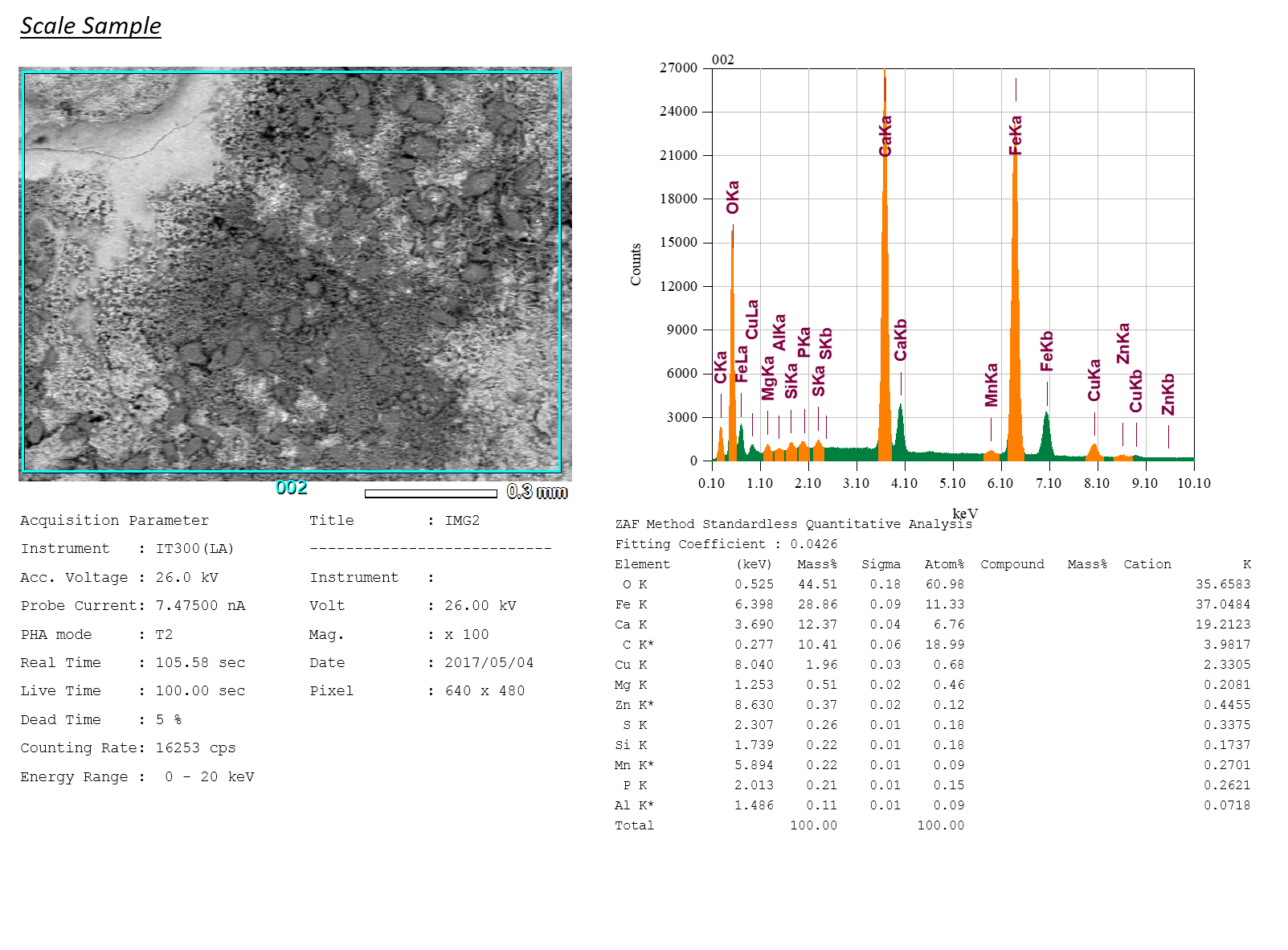

Energy-dispersive X-ray spectroscopy (EDS) is a quick and non-destructive method of determining the elemental composition of a material. Our SEM is equipped with JEOL's sensor and software delivering elemental analysis that is both highly accurate and fast.

EDS can be used to help you find exactly what you are looking for in your sample or as part of your material analysis needs. EDS can be provided as a standalone service or as part of XRD and / or particle sizing.

The standard EDS reporting includes and image of the area scanned, the elemental peak graph, a quantitative elemental analysis table and a setting reference table.

We also offer line scan and topographical mapping. These scans provide elemental distribution and concentration on selected area or a certain direction offer insight into the distribution of elements. They are very useful for coating, corrosion, plating and structural distribution.

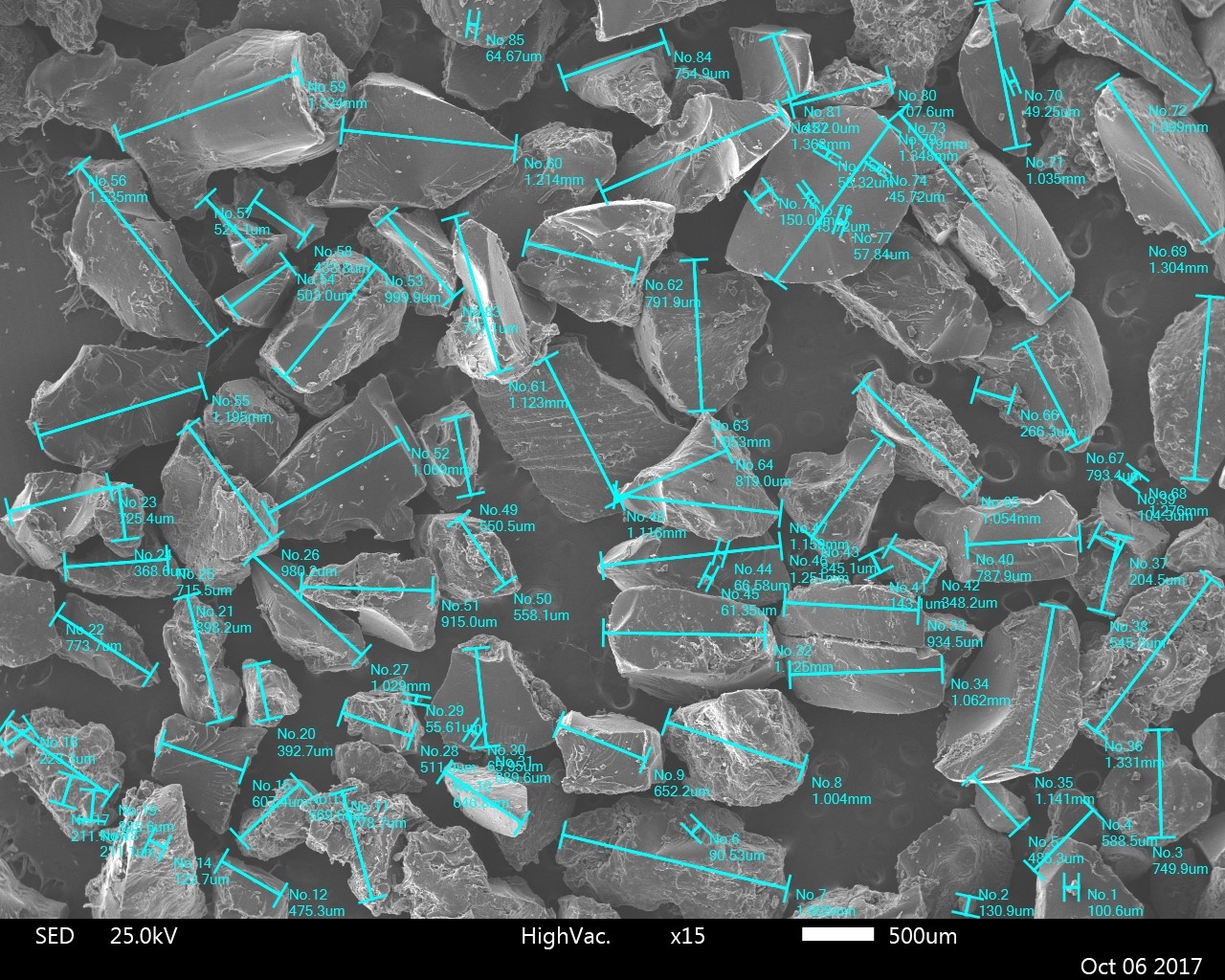

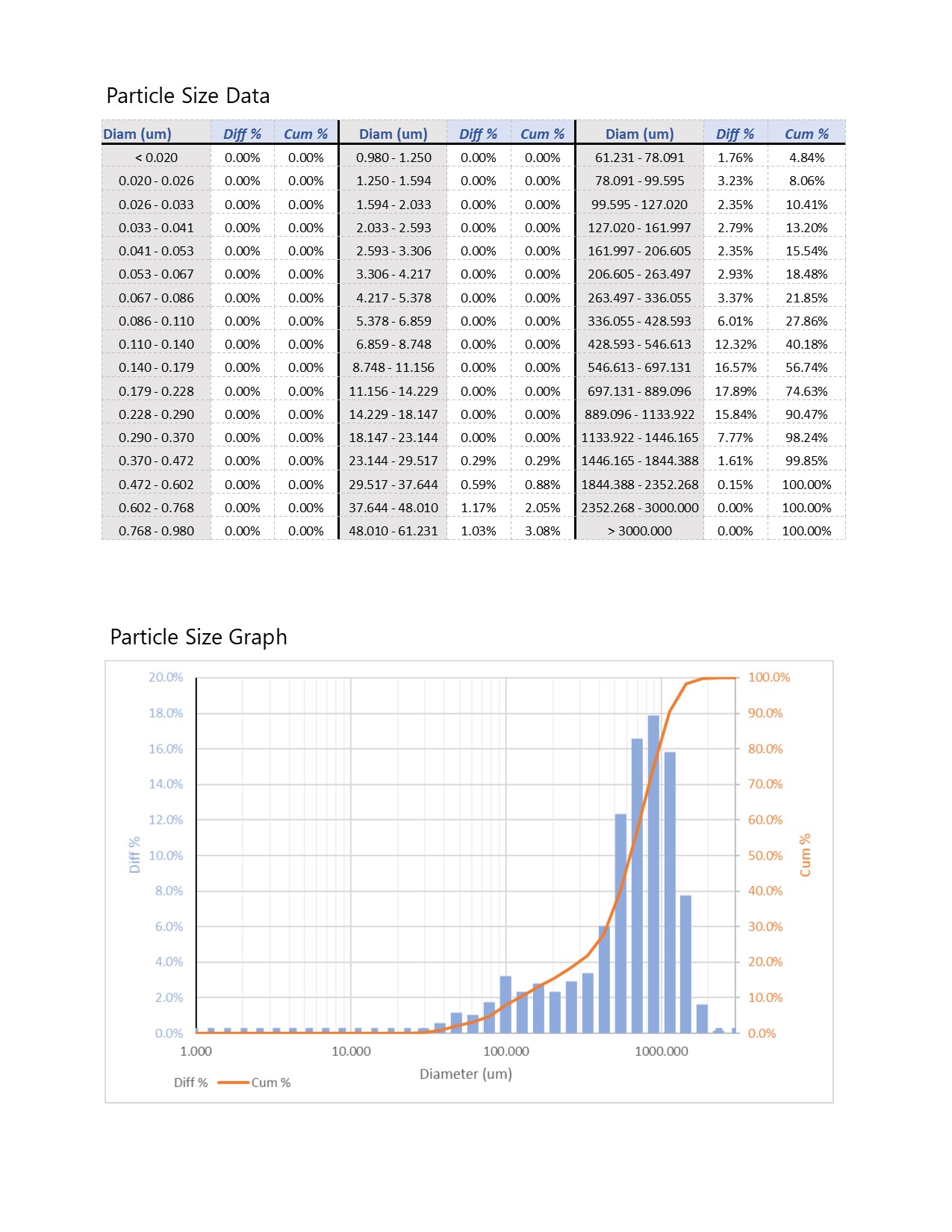

The SEM can be used for particle sizing. SEMx offers SEM based particle sizing based on the ASTM method.

Some materials are not suitable for Laser Particle Sizing due to fragility, solubility, high density or transparency. SEM based particle sizing offers a great option.

SEMx has fully automated the tasks involved in producing the histograms and reports eliminating any human introduced data errors. The SEM particle size report mirrors the output from the Laser Particle Sizer creating consistency.

Copyright 2016 Semx Incorporated